Enquire Now

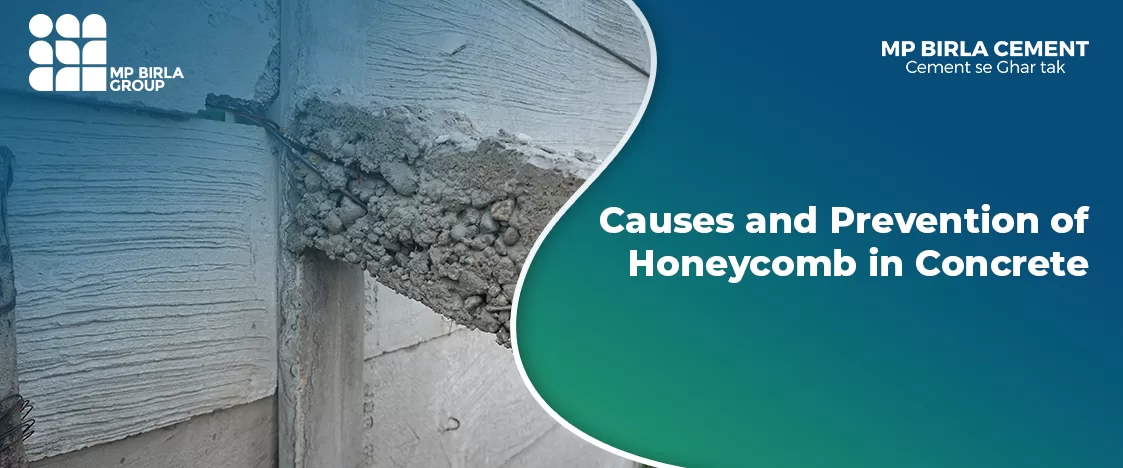

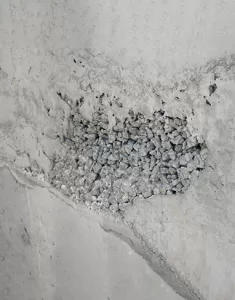

Have you ever noticed rough textures, cavities, voids or gaps on the surface of finished concrete? These occurrences are caused majorly due to air voids because the concrete could not fill up the space entirely. It resembles a honey bee nest and therefore gets the term ‘honeycomb in concrete.’ Usage of the best cement for concrete can ensure that this occurrence is avoided.

But before we talk about which cement works best to prevent this phenomenon, let us explain it to you further.

Honeycomb in concrete is a serious issue that needs to be dealt with at the earliest. It decreases the overall strength of the concrete and makes the reinforcements vulnerable. This occurrence is easily visible on the concrete surface when the formwork is removed. It reveals itself as concrete that has a rough and stone-like surface with coarse aggregates caused by air voids.

What causes honeycomb in concrete?

- Lack of proper workability of concrete

- Concrete that is too stiff or has already been set before it could be placed

- Inadequate vibration of concrete formwork caused the coarse aggregate

- Particles to settle down unevenly

- Use of excessive amounts of large-sized aggregate

- isproportionate use of reinforcements

- Inadequate formwork that is not rigid and watertight

- Dropping concrete from a height that affects its workability

- The use of heavy reinforcements such as steel or inappropriate bar placement prevents the concrete from flowing easily

- Inadequate work on part of the worker

Since prevention is always better than cure, it’s always best to avoid honeycombing in concrete than to repair it after the damage has been caused. Using good quality cement such as MP Birla Cement Perfect Plus is always a good start. But here are a few other ways to avoid honeycomb in concrete.

How can you prevent honeycomb in concrete?

- Ensure that the concrete does not freefall from a distance of more than 1.5 meters.

- Take care to check the workability of the concrete mix.

- The concrete mix being used should have an appropriate amount of fine aggregate particles. This is because the fine aggregate particles will seal the voids and gaps between the coarse aggregate particles easily and properly.

- The concrete should be placed with precision and care to ensure that segregation does not occur and that all the materials are adequately compact.

- Check that the formwork is rigid, well braced and watertight. Improper formwork will lead to penetration of air and water pockets.

- Ensure that the reinforcements and concrete sections are shaped and placed adequately such that the concrete can flow around the reinforcements to fill the formwork.

Now that you are aware of the ways you can prevent honeycomb in concrete, let us discuss the ways you can repair this phenomenon if it does occur.

- Remove all the loose aggregate and concrete from the affected honeycombed area. Do this gently with the help of a wire brush.

- Next, clean the concrete surface of dirt and fine particles with a brush. Wash the surface with water and allow it to dry for about 2 to 3 hours.

- Install a formwork if required or apply a high-strength grout.

- Prepare a grout mixture with water and MP Birla Cement Ultimate. Be mindful of the water quantity used so that it doesn’t get too slurry or stiff.

- Fill the affected honeycombed area with the grout mixture.

- Remove the formwork if it was applied and cure the surface. Allow it to dry for about 24 hours.

It’s important to keep in mind that honeycomb in concrete is not a serious issue if it covers a small area. But if the honeycomb structure occupies a large area or depth in the existing concrete structure, then it can pose a serious threat. Using the best cement for concrete such as MP Birla Cement is a step towards ensuring that honeycomb in concrete does not occur.